Our company's products are manufactured using NTS Соmplех technology – an innovative development system that has allowed a new generation of fuel initiators to be combined with a combustion catalyst, based only on organic compounds (without the presence of metals), harmless to internal combustion engine systems.

The NTS Complex fuel modifier enhances speed and refines the fuel combustion process without changing the chemical structure of the fuel, or increasing the cetane or octane fuel number.

The use of fuel modifier allows the production of modified fuel, which has the following essential effects.

Basic information, certification, security

Research into fuel catalysts has been ongoing since the mid-1970s. The first areas where catalysts were tested and used were aerospace.

It is a product that has been successfully manufactured and supplied to larger industrial, transport and agricultural enterprises for many years in the form of a concentrated product, used to modify diesel in the tanks of their own petrol stations, or to be applied directly to the tanks of trucks, buses, tractors, passenger cars and other diesel machines and mechanisms. The TMD modifier is also supplied in tablet form, primarily to petrol station networks for individual use.

Tariff classification of the TMD Fuel Modifier: CN 3811 900000 = Additives for mineral oils other.

The import and use of a TMD Modifier corresponds to European Union Regulation EC 1907-2006 REACH, EU Regulation 2018/830 as well as European Union-CLP Regulation on classification, labelling and packaging (EC No 272/2008) - see the relevant

Safety Data Sheet Safety Data Sheet.

The main issue to be solved by the fuel modifier based on NTS Complex technology is the practical elimination of the problem of incomplete combustion of fuel.

The TMD fuel modifier does not change the physico-chemical properties of diesel fuel. It was developed and manufactured on an organic basis, that is, it contains no metals, and it is also completely inert against any metals, their alloys and other components of internal combustion engines. This fact is also confirmed by the results of laboratory tests of the TMD Modifier, carried out by SGS Prague's inspection and certification body, and enshrined in

SGS Test Protocol No 55728 SGS Test Protocol No 55728 and

SGS Results Evaluation SGS Results Evaluation of 26.11.2020.

The TMD Modifier is perfectly safe for all engine types as well as their injection systems (EURO 5+, EURO 6). The concentration of the TMD modifier in diesel fuel is so small that any damage is out of the question. They do not form any deposits in the tanks of vehicles, mechanisms or in the tanks of filling stations.

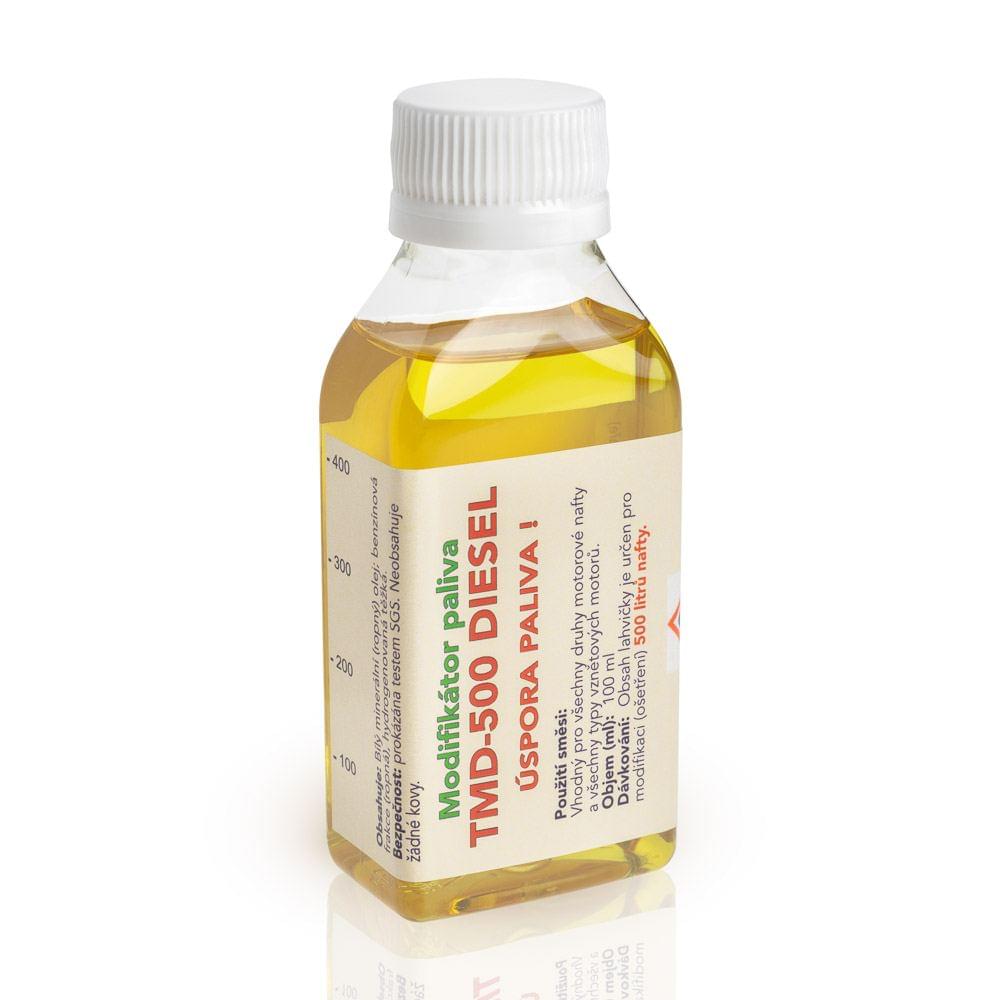

Visually TMD is similar to viscous light yellow liquid, easily dissolved in hydrocarbons.

The operation of the TMD Modifier is based on the forced structuring of substances that participate in the gaseous and liquid phase oxidation reactions (having a chaotic molecular structure prior to TMD application) and which, after TMD application, produce stable spatial structures whose molecules are the same distance between them - see Illustration of the molecular distance before and after use of the TMD Modifier.

This results in a significantly more complex process of hydrocarbon combustion, which is as close to an ideal response as possible, reducing the chemical losses caused by the lack of combustion and thereby not only reducing fuel consumption and emissions of pollutants into the air, but also increasing the efficiency of combustion engines. At the same time, the temperature of the exhaust will only increase slightly.

Package and concentration

The TMD Modifier is supplied in a liquid state with high concentration for industrial purposes (e.g. 100 ml TMD-10.000 is sufficient for modification of 10.000 litres of diesel fuel), and the method of its use is simple pouring of the measured amount of TMD into the tank of the pumping station, where automatic autonomous “modification” of diesel fuel takes place within 20-40 minutes, without the need for mixing or other interventions. The modifier shall be "distributed" evenly throughout the tank.

For customers who do not have their own filling station, we offer a small package of liquid modifier TMD - bottles of 100 ml with a lower concentration, which are used to fill the modifier TMD directly into the vehicle tank during refuelling. The main options are concentrations when one 100 ml bottle is enough to modify 50, 100, 200, 400 or 500 liters of diesel fuel.

Some of our customers prefer to use the TMD modifier in the form of tablets marked TMD-T, and we also offer this option for normal daily use. This option offers a zip lock package with 10 tablets and is available in four basic versions: 1 tablet per 20, 50, 100 or 200 litres of diesel fuel. The pills are placed in the filling pistol before refuelling and together with the pumped diesel fuel are placed in the fuel tank. They operate in a manner similar to the TMD liquid modifier, i.e. they are completely dissolved and the modifier is evenly distributed throughout the fuel tank.

Samples of liquid TMD Modifier packaging

Package and dosing TMD

(liquid and tablet form)

TMD liquid modifier pack | Liquid TMD Type Label | Liquid TMD concentration designed to modify litres of diesel | TMD tablet label | 1 tablet

designed to modify liters of diesel | 10 tablets =

= 1 sachet designed to modify liters of diesel |

|---|

| 100 ml | TMD-50 | 50 | TMD-T-20 | 20 | 200 |

| 100 ml | TMD-100 | 100 | TMD-T-50 | 50 | 500 |

| 100 ml | TMD-200 | 200 | TMD-T-100 | 100 | 1.000 |

| 100 ml | TMD-400 | 400 | TMD-T-200 | 200 | 2.000 |

| 100 ml | TMD-500 | 500 | - | - | - |

| 100 ml | TMD-5.000 | 5.000 | - | - | - |

| 100 ml | TMD-10.000 | 10.000 | - | - | - |

TMD liquid modifier pack | Liquid TMD Type Label | Liquid TMD concentration designed to modify litres of diesel |

|---|

| 100 ml | TMD-50 | 50 |

| 100 ml | TMD-100 | 100 |

| 100 ml | TMD-200 | 200 |

| 100 ml | TMD-400 | 400 |

| 100 ml | TMD-500 | 500 |

| 100 ml | TMD-5.000 | 5.000 |

| 100 ml | TMD-10.000 | 10.000 |

TMD tablet label | 1 tablet

designed to modify liters of diesel | 10 tablets = 1 sachet designed to modify liters of diesel |

|---|

| TMD-T-20 | 20 | 200 |

| TMD-T-50 | 50 | 500 |

| TMD-T-100 | 100 | 1.000 |

| TMD-T-200 | 200 | 2.000 |

TMD modifier composition

According to STO Standard 37342250-005-2013, the composition of the TMD modifier is as follows:

- Ethyl acetate GOST 8981-78 or CAS 141-78-6;

- n-Butyl acetate GOST 8981-78 or CAS 123-86-4;

- complex esters of glycerol and monobase carboxylic acids that contain an unbroken chain with an even number of carbon atoms (C4-24, including carboxylic carbon) according to GOST 1129-93 or CAS 91080-23-8;

- mixture of alkylnaften and alkyl aromatic hydrocarbons according to GOST 26377-89 or CAS 64742-52-5 or both. 64742-54-7;

- Industrial White mineral (petroleum) oil – NUTO H 32 (ExxonMobil);

- Naphtha (petroleum), hydrotreated heavy - ShellSol D-60.

Presentation - Fuel modifiers

The technology family "Organic Series ™"

They are intended for professional engine protection and to reduce fuel consumption in internal combustion engines.

FAQ

Question:

Where does the additional power come from?

Answer:

Normal fuel is burned in the engine combustion chamber, burning about 70-85% of the fuel volume, burning the rest in the catalytic system and leaving in the form of soot (carbon) through the exhaust system. The upgraded fuel, using an NTS Complex based modifier, burns with minimal losses (burning about 98-99% of the fuel volume). Thermal energy, which is usually lost due to incomplete combustion, goes precisely to boost engine power.

Question:

What enhances the potential/durability of the engine, catalyst, exhaust systems and oil?

Answer:

By burning fuel at full capacity, the engine always stays clean and operates in near-ideal conditions. This extends the life of the engine by up to 30%. The full combustion of fuel in the combustion chamber also reduces significantly the load on the oil, catalyst and exhaust system.

Question:

Why is modified fuel greener than conventional fuel?

Answer:

Carbon and carbon monoxide emissions are reduced as a result of fully burning the fuel. There is also a significant reduction in emissions of nitrogen oxides and soot. The concentration of pollutants in the exhaust gases can be reduced by up to 30-50%.

Question:

What benefits do NTS Complex fuel modifiers offer?

Answer:

Savings in fuel consumption are due to improved fuel combustion. If the car/engine is powered by a modified fuel, it will increase the range by 7-15% compared to the regular fuel, thus saving fuel in this proportion.

Question:

Can I use NTS Complex fuel modifiers permanently?

Answer:

It's possible, and even necessary! In contrast to an additive containing detergents (for which permanent use is not recommended), the use of a NTS Complex fuel modifier is recommended on a permanent basis. However, it is imperative to follow the prescribed dosage to achieve optimal effect!